WARREN, Mich. — General Motors is poised to introduce a transformative electric vehicle (EV) battery technology that could significantly lower production costs and enhance profitability for its largest electric SUVs and trucks.

These innovative lithium manganese-rich (LMR) prismatic battery cells are slated for deployment in full-size electric models, such as the Chevrolet Silverado and Escalade IQ, starting in 2028.

The new battery technology features more abundant and cost-effective minerals, including magnesium, thereby reducing reliance on cobalt and nickel, which are currently prevalent in EV batteries produced by GM and other manufacturers.

The choice of battery chemistry can influence a range of factors, including the vehicle’s range, safety, energy efficiency, and charging capabilities.

“LMR unlocks the premium range and performance at an affordable cost,” stated Kurt Kelty, GM’s vice president of battery, propulsion, and sustainability, during a recent media event at the automaker’s technology and design campus in suburban Detroit. “It’s a game-changing battery for electric trucks.”

GM’s ambition to lead in this technology follows the announcement by rival Ford Motor, which recently expressed intentions to launch its own “game-changing” LMR batteries before the end of the decade.

While LMR batteries have been in existence for several decades, their shorter lifespan has historically been a major drawback, according to Sam Abuelsamid, vice president of market research at the automotive advisory firm Telemetry.

GM asserts it has addressed this issue with the development of its LMR batteries, crafted in partnership with LG Energy Solution.

The joint venture, Ultium Cells, plans to commence commercial production of these prismatic cells in the U.S. by 2028, with an initial production phase slated to begin at an LG facility by late 2027.

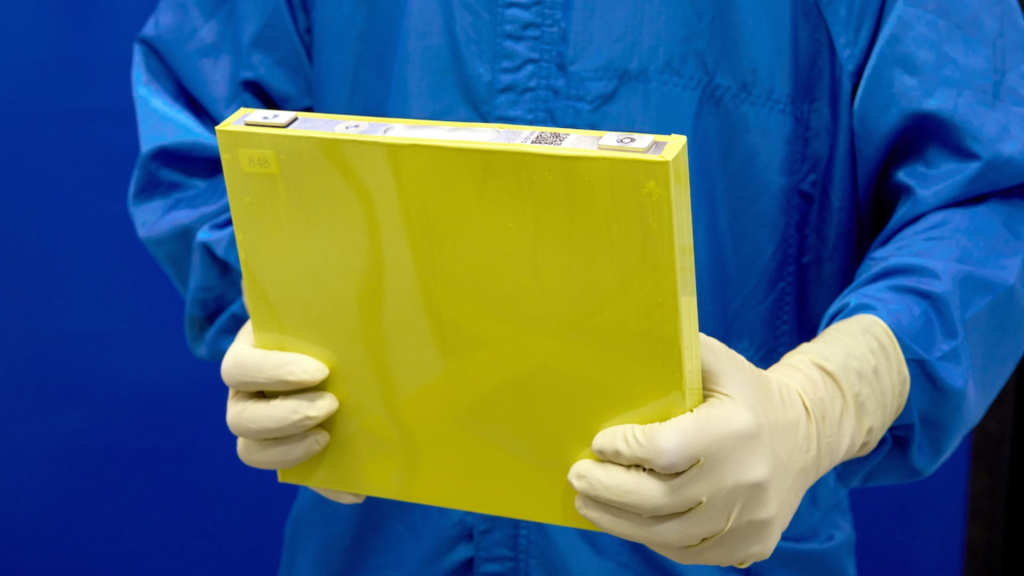

LMR prismatic cells

The term ‘prismatic cells’ refers to the square shape of the batteries, which have been traditionally used in hybrid vehicles like the Toyota Prius and more recently in electric vehicles.

For years, GM has favored rectangular “pouch” cells in the U.S. while utilizing cylindrical cells in China. The company began researching manganese-rich lithium-ion battery technology in 2015, accelerating its development considerably in recent years.

GM anticipates that the new prismatic LMR batteries and associated technologies will reduce the weight of its large electric vehicles by hundreds of pounds. The new battery packs are expected to contain 50% fewer parts and significantly fewer modules, or cell cases, compared to existing battery packs.

In EVs, individual battery cells are typically grouped into modules, and multiple modules are integrated into battery packs for vehicle installation.

Kelty indicated that LMR batteries will complement GM’s existing pouch cell technology, formerly branded as Ultium, as well as upcoming lithium iron phosphate (LFP) prismatic cells intended for smaller, entry-level EVs.

“We’re going through a massive growth phase on the EV side of our business,” Kelty said, noting that GM has surpassed Tesla as the leading EV battery manufacturer in North America. “We’re really building an electrification powerhouse.”

GM expects the LMR prismatic battery cells to deliver 33% higher energy density, translating to additional miles of range compared to the best-performing LFP cells, all while maintaining a competitive price point.

While Kelty did not disclose the specific costs associated with the batteries, commonly measured in dollars per kilowatt-hour, he confirmed a cost reduction of $60 per kilowatt-hour was achieved last year.

A recent BloombergNEF battery price survey indicated that the average cost of battery packs for electric vehicles dropped by 20%, reaching $115 per kilowatt-hour in 2024.

Abuelsamid, who transitioned from engineering to analysis, estimates that GM’s battery packs featuring LMR technology are likely to cost between $80 and $90 per kilowatt-hour, a significant decrease compared to the current rate of at least $125 per kilowatt-hour for GM’s existing batteries.

GM has not confirmed whether vehicles utilizing LMR batteries will be profitable at the time of their launch. However, the automaker reported that nearly 50% of its current EVs exhibited variable profit positivity in the first quarter, meaning they generated sufficient revenue to cover production costs.

‘Next step’

Kelty referred to LMR technology as the “next step” in GM’s electric vehicle strategy. The automaker has invested billions in electrification as part of an ongoing, albeit scaled-back, initiative under CEO Mary Barra.

In 2021, Barra announced that GM aimed to exclusively offer electric vehicles by 2035, with an investment commitment of $35 billion between 2020 and 2025. However, the company has since stated that consumer demand—lower than initially anticipated—will guide its EV development strategy. The total investment made thus far in electric vehicle initiatives remains undisclosed.

GM aims to mitigate barriers to consumer adoption of electric vehicles by addressing major concerns such as cost and range, while also acknowledging other challenges like charging infrastructure and consumer education.

The company intends to provide over 400 miles of range in its electric trucks while achieving substantial savings on battery pack costs compared to current electric vehicle offerings.